CBH have introduced several new storage/pay grades for the 2023 harvest. Some have been floated for a while now, whereas others have been introduced during harvest to combat seasonal quality issues from the early receivals in the north.

I thought it worthwhile to have a look at these new grades again and explain how they can impact your bottom line if not handled correctly. I’ll also touch on the Quality Optimisation rule changes of which there are a couple.

Hopefully, by the end of this article (which will also include a handy Cheat Sheet), you’ll have a better understanding of these new grades and how best to go about achieving the

most profitable outcome for your delivered grain.

AWWT (formerly known as AWW2)

This is a consolidated grade for wheat that was previously classified as ASW1 (protein below 9%), AGP1 and in most years, FED1 (unless there are issues with falling numbers). After two record harvests back-to-back, CBH felt the need to simplify their segregations of wheat and, in the process, hope to better meet market demand for feed-specification grain. This grade will also accept up to 13.5% moisture and

10% screenings.

So, is that Sayonara to ASW1? Well, not exactly.

You won’t see it as a storage grade when delivering ASW1 quality wheat; it will be stored as AWWT along with your AGP1. Eventually it is expected that buyers will price AWWT at the same level as ASW1, but some of the major players have so far declined to offer a price stating that they want to wait until they see the quality profile of the AWWT segregation before deciding.

So, should I be worried that my “ASW1’ wheat is now AWWT and priced at a discount or not on my contracts?

The simple answer is no – CBH have provided the ability to optimise AWWT to ASW1 through Quality Optimisation (QO).

Since I’ve mentioned QO, there are a couple of other changes to be aware of:

- ASW9 will be included as a QO grade (meaning you can optimise into it) and

- APW2 will change QO status so it can only be optimised out of, not into.

Utility Wheat Grades – AUH, AUP1 & AUS9

It quickly became apparent, once harvest started in the Geraldton zone, that screenings were going to be an issue this year and, in combination with higher protein, could result in some high protein grain being valued at AWWT levels. As harvest has moved further south, screenings continue to be an issue in all protein ranges. So now we have three new grades to help circumvent this:

- AUH – for AH varieties with high protein (min 13%) and high screenings (max 10%);

- AUP1 – for APW varieties with high protein (min 10.5%) and high screenings (max 10%) and

- AUS9 – for wheat with lower protein (min 9%) and high screenings (max 10%)

With the introduction of AUH, CBH are assuming (or hoping) that buyers will be willing to pay more for it than AUH2 as the protein will be H1 quality. The current premium from AUH to AUH2 is only $2 to $5 so the jury is still out on whether this will increase as harvest progresses.

The advantages of AUP1, on the other hand, are more obvious as this grade will capture tonnes that would otherwise be stored/paid as AWWT due to screenings being over 5%. With the current spread from APW1 to AWWT being -$35, the cliff face is steep. The most recent introduction is AUS9 which will segregate lower protein wheat (min 9%) with screenings between 5 – 10%. Essentially this AGP1 with ASW9 protein levels. Once again, buyers are expected to wait until they see how their existing contracts are filled before making a pricing decision on these new grades. Because of this, I would recommend filling your contracts with the good quality grain and hold the lower spec tonnes to sell later when there is more buyer engagement.

If you have already delivered grain as AWWT before these new grades were introduced, and if these loads meet the standards for the utility grades, CBH operations will automatically regrade them from AWWT to AUH, AUP1 or AUS9 for you.

The next question is what do you do if you are producing these grades?

Do you clean, blend or optimise?

Cleaning wheat these days to increase the overall value of the grain rarely works. Since the introduction of Quality Optimisation, and with some strategic on farm blending, most growers can optimise the overall quality of grain without the inconvenience and cost of cleaning. Blending, or shandying, on farm is a different ball game which can sometimes pay good dividends compared to delivering to CBH and trying to Optimise within the system.

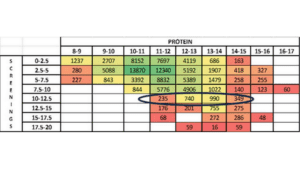

Most of the wheat that has come in thus far has been around 10% to 13% protein and 0% to 10% screenings as per the heat map below. This means it can all be received into the main milling grades and can be Quality Optimised. The tonnes within the circle below are the ones that are just out of spec but could be bought in with some extra time & effort, given these grades can’t be optimised.

When to blend

Even if most of your grain is being delivered into the main milling grades, there are some restrictions, which I have listed below, on how we can quality optimise them into the higher paying grades. In these instances, blending on farm is probably your best option.

Unoptimisable grades

There are some grades that can’t be optimised at all. These are AUW1, FED1 and SEC1. Once in CBH these grades will stay as they are.

Example: You have some H2 (+$10) wheat going in at 3% screenings and you have another paddock with high protein but screenings at 12%, so it’s going FED1 (-$60). You will be better off mixing the two on farm to make AUH2 (-$10). Some of this AUH2 could potentially be used for optimising in to H2 or APW1 later.

Grades that can be optimised out of but not into

There are some grades that can’t be optimised into, only out of. These include H1, AUH2, APW2 and APWN. If aiming to hit these grades you will need to blend on farm rather than deliver and optimise in CBH.

Example: You have some H1 going in to CBH at 14% protein and then some H2 going in at 12.8%. You won’t be able to optimise the H2 up to H1 in CBH due to the restriction even though the protein will average better than 13.2%.

Optimisation buffers

When optimising there are buffers built in to the system. Optimised grades generally need screenings to average below the delivered grade and protein 0.2% above the delivered grade.

Example: A load of APW1 at 2% screenings won’t be able to pull in a load of AGP1 wheat at 6% screenings because the average screenings of 4% is above the buffer zone of 3.5%. It may be more beneficial trying to blend these grades on farm. With that said blending is a tricky art at the best of times and there is a risk both loads will end up as AGP1.

Maximum protein improvement restrictions

Protein can only be improved by a maximum of 1% with the optimiser. This is particularly important for noodles.

Example: A load of ANW2 is delivered at 8% protein and another ANW2 load is delivered at 13% protein. The average of the two loads would fall right in the middle of the required ANW1 protein window of 9.5 – 11.5% but as the original protein levels are more than 1% outside of the noodle window, they can’t be optimised into ANW1. These loads would need to be blended on farm to make ANW1

When to clean

In regard to cleaning, it really comes down to the cliff face in price between the original grade and the final grade less cleaning costs. Cleaning costs need to take into account the volume of seconds that need to be removed, the value of the seconds grain and what is the value of the cleaned grain. Other important factors to consider include the time involved in cleaning (although you may not have to clean

every tonne) and who is actually manning the cleaner in the paddock.

Example: Cleaning AUN1 (-$100) or ANW2 (- $75) to get it into ANW1 will work.

Example: Cleaning FED1 (-$70) or AUW1 to achieve APW1 (base) or H2 (+$10) will work.

Example: Cleaning AGP1 (-$35) to get in to APW2 (-$10) is unlikely to work.

If you have a lot of lower quality grain it might be worth considering isolating it and delivering it to the domestic stock feed markets. It could save a lot of harvest headaches and achieve a similar financial result.

For cleaning barley to go from BFED1 to Malt1 the same principles apply. If the cliff face is greater than the true cost of cleaning then there may be a benefit in cleaning. Be aware, when cleaning to make malt, it is not just screenings at the bottom of the pan that you need to watch (less than 20%) but also retention of grain at the top of the pan (more than 80%). Ideally you will have a contract with a good malt

spread in place before pulling out the grain cleaner as we have seen years where clients clean grain and hit the malt grade only to see malt premiums fall below the true cost of cleaning.

Another option is recalibration of the header via higher fan speeds, sieve adjustments etc. to prevent some of the smaller grain entering the sample. It’s important to note that this is more effective on pinched grain (which is long and shrivelled) as opposed to small underdeveloped grain. The closing of the sieves can compromise the effectiveness of the fan so concentrate on one aspect at a time and use loss

trays to measure the outcome.

Another bit of advice we often tell growers who are finding quality issues with no obvious solution is that sometimes moving operations to another area can provide the better quality they are chasing. It is amazing how often that harvesting elsewhere is the key to solving quality issues. It also pays to remember that often the grade spreads to lower grades disappear once buyers are more confident in buying

these grades.

In conclusion, apart from actually taking the crop off in a safe & timely manner, growers also have to think about what to do with grain that isn’t making the usual premium milling grade specifications. This isn’t unusual in itself as there are always quality issues to deal with but with new grades (some with no prices), changes to Quality Optimisation rules, blending on farm, possibly cleaning?

It’s enough to make your head spin.

If this sounds like something you might need help with, or advice on, then please get in touch with one of Grain Marketing advisors here at Planfarm. In the meantime, print out the Cheat Sheet below – it might help point you in the right direction.